Setting a New Benchmark in Industrial Lifting

Guanhui proudly announces the successful delivery and commissioning of a 150/32 ton bridge crane for a leading stainless steel manufacturing plant. This achievement marks a significant leap in delivering powerful, custom-engineered solutions for complex heavy industry applications. Entirely designed, manufactured, and installed by Guanhui’s in-house team, the crane is now fully operational, reflecting the company’s unwavering commitment to excellence.

Technical Specifications of the 150/32 Ton Bridge Crane

Heavy-Duty Design for Demanding Loads

This overhead bridge crane offers a dual-lift system: 150-ton main lift and 32-ton auxiliary lift, tailored for operations needing flexibility between massive and medium-scale loads. The robust double-girder structure ensures enhanced stability and precision.

Tailored to Client Specifications

Developed in close collaboration with the client, the crane design was customized to fit spatial limitations, workflow, and lifting patterns, optimizing both space and load flow.

Certifications and Safety Compliance

Guanhui’s operations and this crane system are ISO 9001, 14001, 45001 certified, ensuring top standards in quality management, environmental responsibility, and occupational safety.

Precision Manufacturing and Quality Control

End-to-End Production Under One Roof

From steel fabrication to electrical wiring and final assembly, all components were produced in Guanhui’s state-of-the-art facility, ensuring superior quality control and faster production cycles.

Performance-Verified Handover

After installation, the crane passed final commissioning tests, demonstrating seamless control, load stability, and system responsiveness. The client signed off with full satisfaction.

Installation and Commissioning Success

Swift, Safe, and Efficient Setup

The installation took three weeks, using modular pre-assembly and strategic logistics to minimize plant downtime. Safety officers and engineers ensured on-site compliance throughout.

Boosting Stainless Steel Production Efficiency

The crane now plays a pivotal role in moving heavy steel billets and components, reducing intra-facility transport time by over 30% and lowering manual handling risks.

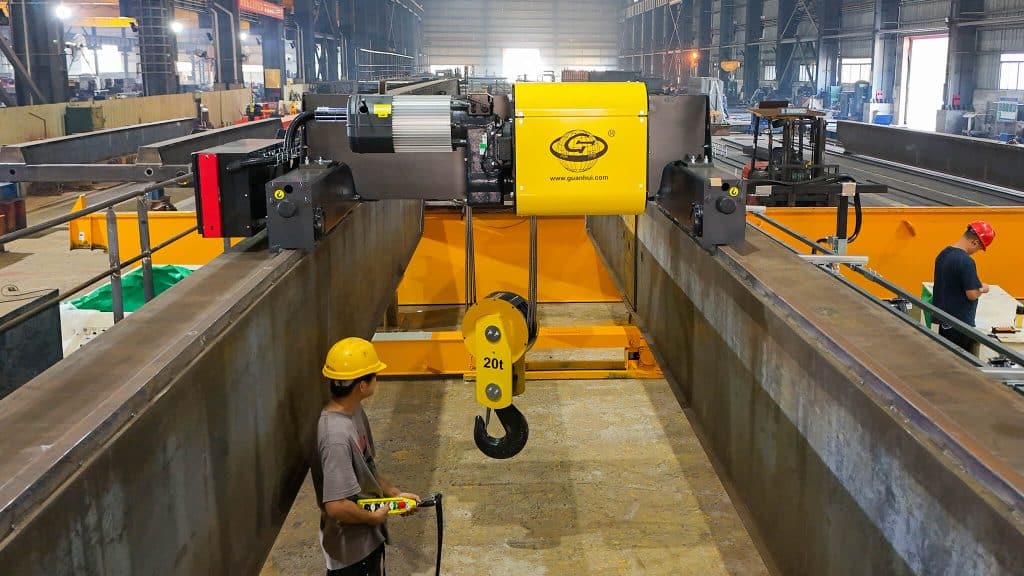

Operator-Friendly Innovations

Modern control panels, ergonomic operator stations, and remote control integration make the system user-friendly, while enhancing accuracy and responsiveness during heavy-load operations.

Guanhui’s Expertise in Industrial Cranes

Decades of Industrial Experience

With over 30 years of crane manufacturing expertise, Guanhui has delivered 1,000+ custom lifting systems across industries like energy, metallurgy, and shipbuilding.

Global Reach and Crane Export Milestones

Guanhui’s products are trusted in over 60 countries, backed by a global network of partners and after-sales specialists.

Reliable Custom Solutions for Heavy Industry

Purpose-Built for Every Environment

Whether dealing with extreme heat, corrosive atmospheres, or tight spaces, Guanhui designs cranes to withstand real-world conditions with high uptime and low maintenance needs.

End-to-End Partnership Approach

From consultation to commissioning and long-term support, Guanhui ensures seamless communication and customer satisfaction at every stage.

Advantages of the 150/32 Ton Bridge Crane

Dual-Functionality for Versatile Operations

The system handles both ultra-heavy and moderate lifting tasks, improving throughput without the need for multiple machines.

Downtime Reduction and Easy Maintenance

The modular design allows for faster servicing and parts replacement, with built-in diagnostics enhancing reliability.

FAQs

1. What does the 150/32 ton crane capacity mean?

It refers to a dual-lift system: 150-ton main lift and 32-ton auxiliary lift for smaller or precision loads.

2. Is the crane system modular and customizable?

Yes, every Guanhui crane can be tailored to industry needs, spatial layouts, and load types.

3. What certifications does Guanhui hold?

Guanhui holds ISO 9001, 14001, 45001 certifications for quality, environmental, and occupational safety management.

4. What is the typical delivery timeline for such projects?

Design to commissioning generally takes 4–6 months, depending on complexity and customization.

5. Does Guanhui offer international support?

Yes, Guanhui provides global installation, training, and maintenance support.