You see big changes in how stainless steel coils are handled. The Automated Overhead Crane for Stainless Steel Coil Handling is leading in 2025. With over a decade of experience in crane automation, Guanhui has developed solutions that perfectly balance precision, safety, and performance. This technology stacks coils very carefully. It keeps them steady and makes work much safer. When you use these systems, you make fewer mistakes. You also finish each step faster. The newest cranes can lift up to three coils at one time. They do this with special electromagnetic fixtures and accurate LiDAR scanners.

Automated crane-served stores now hold 30% more coils. You also see faster handling and softer coil movement. This makes your work easier and safer.

| Metric | One Coil | Two Coils | Three Coils |

|---|---|---|---|

| Average Pose Estimation Error | 1.1% | 1.1% | 1.2% |

| Total Processing Time (sec) | 3.6 | 3.4 | 4.7 |

To stay ahead in the steel industry, you need automation. It helps you work better and make fewer mistakes by hand.

Challenges in Coil Handling

Manual Limitations

Manual coil handling has many problems. You need trained workers to use cranes and forklifts. This makes labor more expensive and stresses your team. Workers must always pay close attention. This can make them tired and cause mistakes. Even small mistakes can damage coils or put them in the wrong place. How well things go depends on how skilled the worker is. If a worker gets tired or loses focus, mistakes happen more often. Old coil holders are heavy and hard to move. They do not let you move coils exactly where you want. This makes it hard to keep coils in the right spot. These problems slow down your work and cause more breaks in production.

Studies show manual coil handling costs more in labor and has more mistakes. You pay extra for fixing things, insurance, and repairs because of these errors. Manual work also takes longer. This slows down how much you can make and lowers your output.

Safety Risks

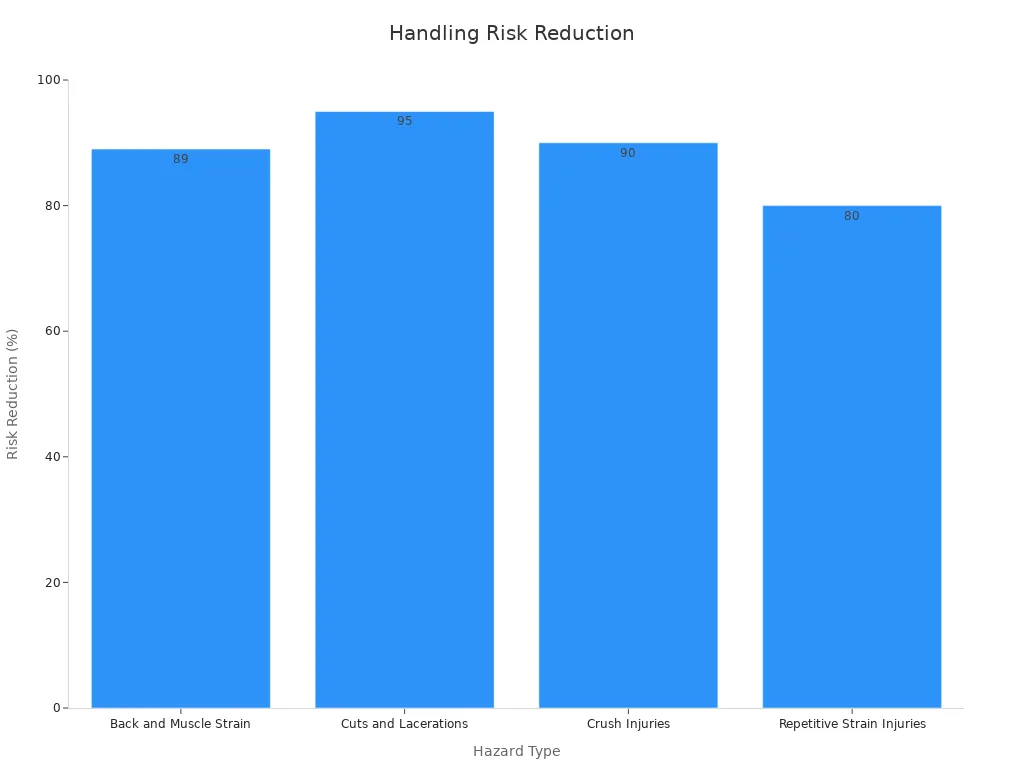

Manual coil handling can be very dangerous for workers. Lifting heavy coils and doing the same moves over and over can hurt backs and muscles. Coils have sharp edges that can cut or scrape skin. Moving coils by hand can crush fingers or hands. These injuries hurt your team and cost you money and time. For example, injuries at work mean lost hours and higher insurance bills. You might even get fined if you do not follow safety rules.

| Hazard Type | Manual Handling Frequency/Impact | Automated Handling Impact | Reduction in Risk (%) |

|---|---|---|---|

| Back and Muscle Strain | Affects 45% of workers annually | Less than 5% | 89% |

| Cuts and Lacerations | Frequent due to sharp edges | Minimal | 95% |

| Crush Injuries | Common during coil positioning | Rare | 90% |

| Repetitive Strain Injuries | High due to repetitive motion | Low | 80% |

Inefficient Space Use

Old coil handling systems take up too much floor space. You often see slowdowns in your work because space is not used well. When you move coils by hand, you cannot stack them as well. This means you lose money and have more breaks in work. Your work moves slower, and you spend more to run things.

- Poor material flow and slow handling lose money.

- Slowdowns happen when space is not used well.

- Old systems do not have automation, so work is not smooth.

- Overhead crane systems save space by moving coils up high.

| System Type | Floor Space Utilization |

|---|---|

| Traditional Coil Handling System | 3 times more floor space |

| Combination Space Saver System | 1/3 of traditional system |

Switching to automated systems helps you use space better, spend less, and get more done.

Automated Overhead Crane for Stainless Steel Coil Handling

Precision Stacking

It is important to stack coils neatly and carefully. The Automated Overhead Crane for Stainless Steel Coil Handling helps you do this well. It uses special sensors and controls to put each coil in the right spot. Robotic palletizers and automatic spacers help make strong and even stacks. This keeps coils safe and your storage tidy. You do not have to rely on a worker’s skill. The system gives you the same good results every time. Automation lets you fit more coils in less space. This makes your warehouse work better.

Sway Reduction

Moving heavy coils can be risky if they swing too much. The Automated Overhead Crane for Stainless Steel Coil Handling uses smart controls to keep loads steady. Sensors and feedback help the crane move smoothly. This means less swinging and more control. The crane works with other machines, like conveyor belts and robotic arms. Everything moves together without sudden stops or jerks. This keeps your coils safe and your team out of harm.

Tip: Sway reduction keeps your products safe and helps protect everyone working nearby.

PLC-Based Control

You want your coil handling to be smart and dependable. The Automated Overhead Crane for Stainless Steel Coil Handling uses PLC-based control systems for this. Siemens SIMATIC PLCs collect data and help make choices fast. These PLCs connect to sensors, switches, and drives to keep crane moves exact. You can watch everything from one control room. The system works well even in hot or tough places. Open protocols let you add new features, like vision systems and laser trackers. Safety tools, like lockout devices and ground sensors, help keep your team and coils safe.

- Real-time checks and KPI tracking help you find problems early.

- Extra safety systems let cranes work alone, so production keeps going.

Integrated Lifting Devices

You need tools that move coils safely and quickly. The Automated Overhead Crane for Stainless Steel Coil Handling uses C-hooks, tongs, and magnets to lift coils. These tools grab and move coils with care. Automation cuts down on mistakes and tired workers. You see fewer accidents and less coil damage. The system works all the time, so you move more coils faster. It can change to fit what you need, keeping your work smooth and steady.

- Integrated lifting devices help you work faster by cutting down on manual delays.

- Automation saves money and puts loads in the right place every time.

- Smart technology, like AI and IoT, makes the system safer and better.

Guanhui crane is known for making these systems. Their skill means you get a system that fits your needs. You get good performance, strong safety, and the newest technology in every Automated Overhead Crane for Stainless Steel Coil Handling.

Key Benefits

Enhanced Safety

Automated coil handling makes your workplace safer. Anti-sway systems and load monitoring help stop accidents. Automated safety tools work fast to protect people. Real-time sensors watch every lift and move. These features lower injuries from lifting heavy coils or touching sharp edges. You can meet safety rules more easily and keep your team safe. The table below shows how each safety feature helps:

| Safety Feature | Description |

|---|---|

| Advanced Load Monitoring | Watches weight all the time and stops too much weight. |

| Automated Safety Mechanisms | Emergency stops and safety tools stop accidents before they happen. |

| Anti-Sway Technology | Keeps loads steady and stops swinging. |

| Intuitive Operator Controls | Easy controls help workers make fewer mistakes. |

| No-Fly Zones | Stops the crane from going into unsafe places. |

Automated Overhead Crane for Stainless Steel Coil Handling systems help lower injuries and keep your work safe.

Higher Productivity

Automation helps you get more work done. Automated cranes move coils faster and with more care than people. You can move up to 30 coils each hour, not just a few. Fast profiling and wrapping lines let you make thousands of meters every day. Operators watch the machines instead of lifting, so they do not get as tired or make as many mistakes. Automated systems keep your work steady, even on long days.

- Robotic handling works with many coil sizes and weights.

- Automated packaging puts on materials fast and wastes less.

- Real-time data helps you find and fix slowdowns quickly.

Cost Savings

You save money in many ways with automation. You need fewer workers, so labor costs go down. You do not have to build bigger warehouses because you use space better. Operating costs drop by 15% or more, and you get your money back in six months or less. Automated systems also lower damage to coils, so you waste less and get better products.

| Financial Aspect | Benefit/Metric |

|---|---|

| Labor Savings | Save $660,000 each year by using fewer workers. |

| Capital Cost Avoidance | No need to build bigger warehouses, saving $600,000. |

| Operating Cost Reduction | Costs are 15% lower and you make 20% more. |

| ROI Payback Period | Most automated systems pay for themselves in 6–18 months. |

| Damage Reduction | Fewer damaged coils, less waste, and better products. |

Workflow Continuity

Automated systems help your work keep going without stopping. Automated Overhead Crane for Stainless Steel Coil Handling cuts downtime by up to 40%. You can run your work 24/7 with fewer stops. Real-time checks and smart repairs help you fix problems before things break. You also plan better with data and get materials right when you need them.

- Setup times are shorter, and one worker can handle many coils.

- Automated scheduling and tracking stop slowdowns.

- Safety systems and automation keep things running, even when shifts change.

Automation gives you steady work and helps you stay ahead of others.

2025 Advancements

Heat-Shielded Components

High heat can make cranes work badly in steel plants. You need parts that stay strong when it is hot. New cranes use heat-shielded materials like magnetite–serpentine concrete and special heat barriers. These keep parts safe and strong, even at 800°C.

| Property | Temperature (°C) | Measured Value | Performance Impact |

|---|---|---|---|

| Compressive Strength | 800 | 12.2 MPa | Stays strong in high heat |

| Splitting Tensile Strength | 800 | 0.48 MPa | Keeps pulling strength |

| Linear Attenuation Coefficient | 800 | 80.9% of normal temperature | Blocks radiation |

| Damage Observations | 800 | Spalling phenomenon | Shows how much heat the part can take |

These features help the Automated Overhead Crane for Stainless Steel Coil Handling work safely and right, even in tough places.

Remote Operation

Remote operation gives you more safety and control. Operators run cranes from safe rooms, so there is less danger and less tiredness. You see up to 40% less downtime from accidents and 25–35% more work done. Remote checks let you watch motors, brakes, and load stress as it happens. You fix problems faster and plan repairs better. Emergency stop and anti-collision tools keep people and machines safe.

- Real stories show more work time and lower costs.

- Remote data lets you act fast, no matter where you are.

Guanhui crane puts all these new things together, giving you a system ready for the future of coil handling.

You get better results with coil handling when you use advanced automation. Guanhui crane’s solutions fix old problems and make work safer and faster.

Real-life stories show that advanced sensors stop accidents and protect your team.

- Automated systems make cranes move up to 50% faster and save money by letting workers do other jobs.

- IoT and AI help with fixing machines before they break and save energy.

Stay ahead in 2025 by using new and smart coil handling from Guanhui crane.

FAQ

What types of coils can automated overhead cranes handle?

Automated overhead cranes can move stainless steel, aluminum, and copper coils. They also work with other metal coils. The system changes to fit different coil sizes and weights. This gives you more ways to use the crane for your work.

How do automated cranes improve safety in coil handling?

Automated cranes have sensors and anti-sway controls. They also use safety zones to help stop accidents. These features keep your team safe from getting hurt. You lower the chance of injuries from lifting heavy coils or touching sharp edges.

Can you monitor crane performance in real time?

Yes, you can watch crane status and load data with IoT dashboards. Real-time checks help you find problems early. This keeps your crane working well and stops surprise breakdowns.

What maintenance do automated overhead cranes require?

You should check sensors, motors, and lifting devices often. Predictive maintenance tools warn you before something breaks. This helps you fix things on time and keeps your crane working well.

How does automation help you save space in your facility?

- You can stack coils higher and closer together.

- Automated systems use space above the floor.

- You get more open floor space for other work.

- You store more coils without making your building bigger.