The 6(5+5)t Overhead Crane features two 5-ton hoists operating in tandem with a specialized spreader beam. Although each hoist is rated for 5 tons, the total structural capacity is limited to 6 tons. This dual-point lifting setup is specifically designed to provide stability for long paper rolls, ensuring the load remains balanced and preventing damage during transport.

6(5+5) ton Paper Mill Overhead Crane Features

Lifting Capacity and Dual-Hoist Configuration

The 6 (5+5) ton Overhead Crane features two 5-ton hoists designed for tandem operation. While each hoist has a 5-ton capacity, the crane’s total structural load is limited to 6 tons. This configuration is specifically engineered for handling long, heavy paper rolls using a spreader beam. By lifting from two points simultaneously, it provides superior stability that a single hook cannot achieve.

Why the Dual Hoist System is Critical for Paper Mills:

| Advantage | Description |

|---|---|

| Stability for Long Loads | Lifts long paper rolls from two points, preventing the load from tilting or swinging dangerously. |

| Prevents Product Damage | Keeps the paper roll perfectly level during transport, reducing the risk of edge damage or telescoping. |

| Precise Positioning | Allows for exact alignment when loading rolls onto winders or machine reels. |

| Synchronized Lifting | Both hoists operate at the same speed to ensure smooth, balanced movement without stress on the load. |

Designed specifically for the paper industry, the 6 (5+5) ton configuration offers the perfect balance of cost-efficiency and operational safety. It provides the dual-point stability needed for large rolls without the expense of a fully rated 10-ton bridge structure.

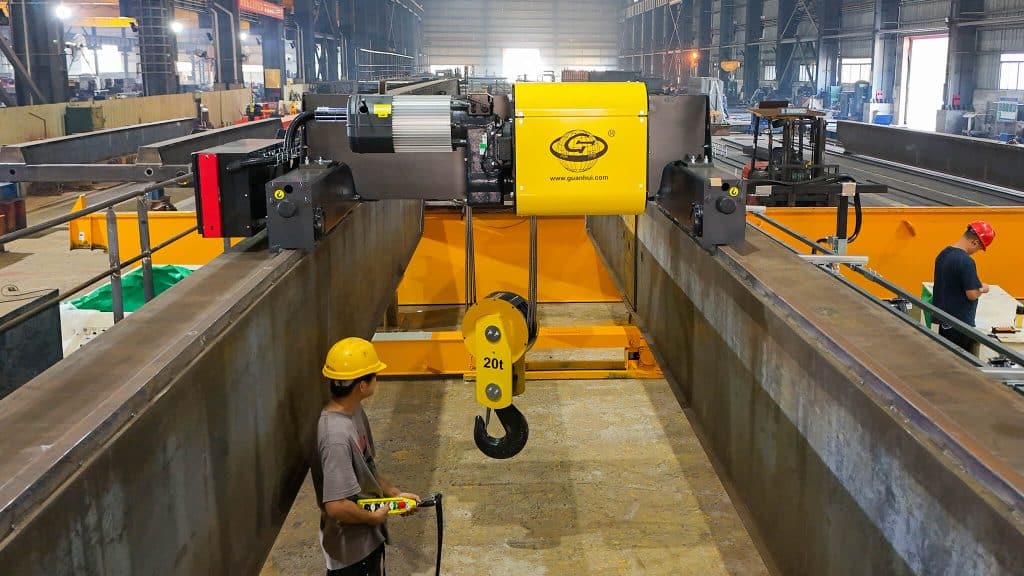

Control Modes and Operational Safety

The 6 (5+5) ton Paper Mill Overhead Crane offers versatile control options tailored to your facility’s layout and operational needs. Each mode is designed to maximize operator safety, visibility, and ergonomic comfort.

| Control Mode | Description |

|---|---|

| Wireless Remote Control (Recommended) | Best for Mobility: Allows the operator to move freely around the paper roll to check rigging from all angles while maintaining a safe distance from the load. |

| Cabin Control | Best for Visibility: An elevated, enclosed cabin provides a panoramic view of the entire workshop, ideal for high-duty cycles and continuous operation. |

| Pendant Control | Cost-Effective: A wired control unit for precise, close-range operation, typically used as a backup or for specific maintenance tasks. |

Why Remote Control is Preferred for Paper Mills: In a busy paper mill, visibility is key. Wireless remote control allows the operator to walk around the large paper rolls and ensure the spreader beam is perfectly aligned before lifting. This eliminates blind spots and significantly improves handling efficiency.

Benefits in Paper Mill Operations

Typical Applications in the Paper Industry:

| Application Type | Description & Function |

|---|---|

| Paper Roll Handling | Transporting finished paper rolls to storage or cutting machines using a spreader beam for stability. |

| Pulp & Raw Material | Handling wood pulp bales or transporting raw materials in the stock preparation area. |

| Scrap & Waste Handling | Moving scrap baskets or recycling bins efficiently to keep the production floor clean. |

| Warehouse Logistics | Stacking and organizing finished goods with precise positioning to maximize storage space. |

Whether handling delicate finished paper or rugged machine parts, the 6 (5+5) ton crane provides the stability of two lifting points combined with the cost-efficiency of a 6-ton structural design.

You get lots of good things with a 6(5+5) ton paper mill Overhead Crane. Its features make paper handling easier for you:

Benefit for Paper Handling | |

|---|---|

Efficiency | Lifts and moves things faster by itself |

Safety | Helps stop accidents at work |

Design Adaptability | Can change to fit your paper jobs |

Improved Workflow Efficiency | Makes work go smoother in factories and storage |

You stay safer, work faster, and move heavy rolls without trouble.

FAQ

How do you control a 6(5+5) ton overhead crane?

You use a pendant, cabin, or wireless remote. Each control type gives you safety and flexibility.