Safety compliance is essential, but it is not always immediately easy or profitable for property owners and contractors. When decision-makers on construction projects prioritize profits over worker safety, the results can be catastrophic.

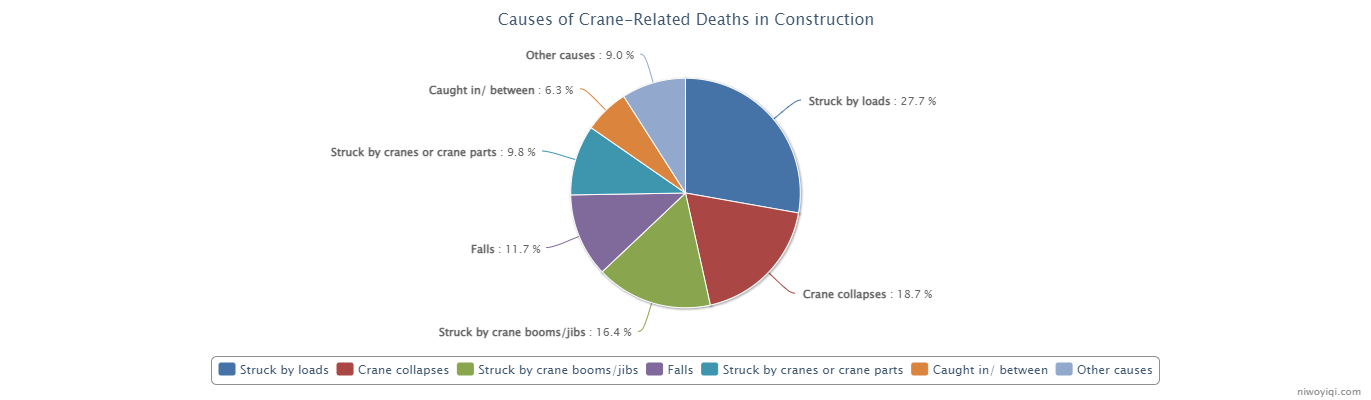

Fatality caused by crane

From 2011 to 2017, the Census of Fatal Occupational Injuries (CFOI) reported 297 total crane-related deaths, an average of 42 per year over this 7-year period. Every year, the average major injury has a cost of over \$200,000, and the average fatality has a cost of over \$4,000,000.

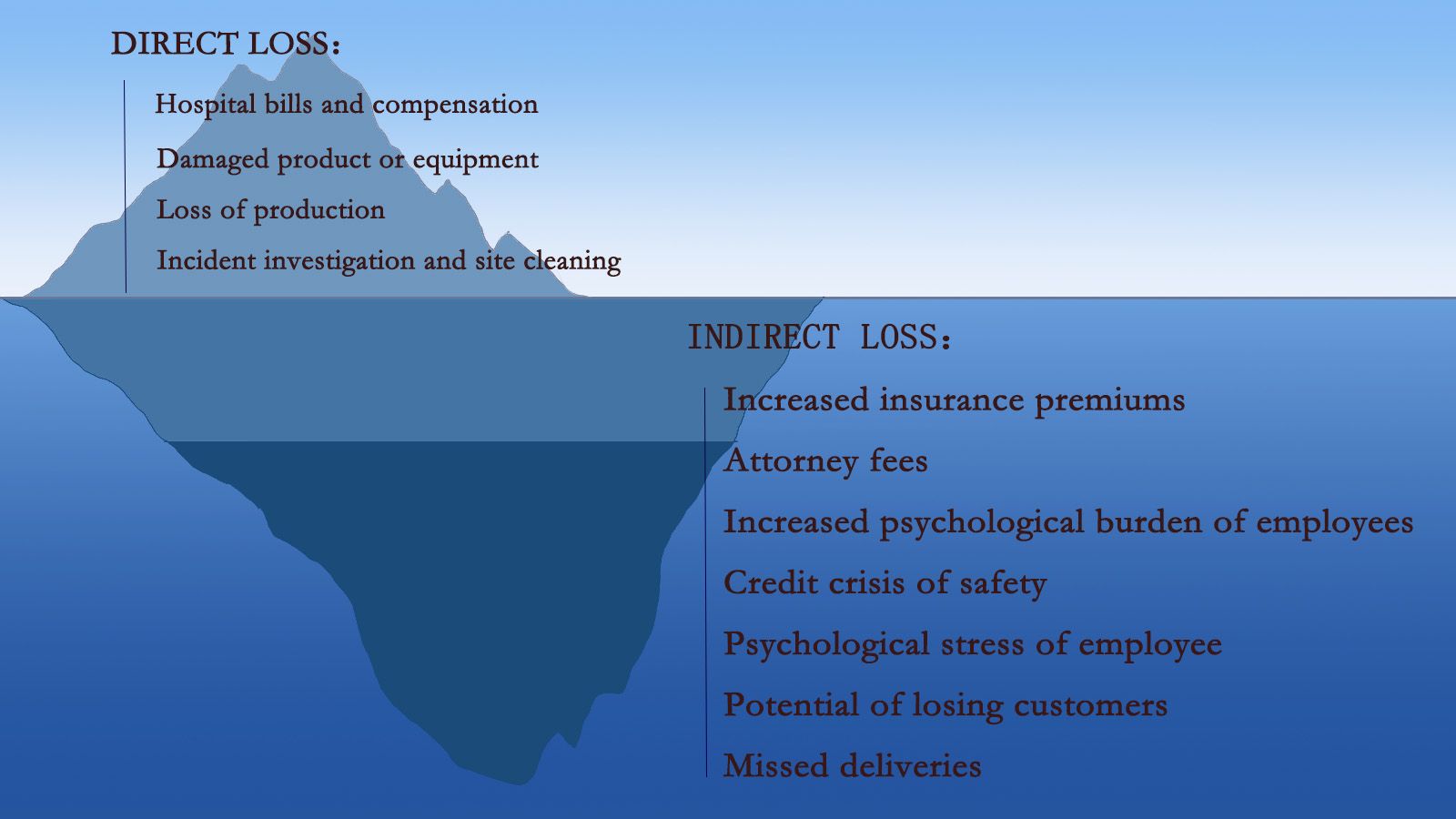

Losses Caused by Accidents

Once you have found the right equipment for the job, we know that it’s vital to keep your crane running. Not only do you have health and safety legislation to meet, but damaged or worn-out cranes will be inefficient and may cost you time and money. As an owner of cranes and hoists, you are responsible for the protection of your staff. Even one accident is too costly for business if it could have been avoided.

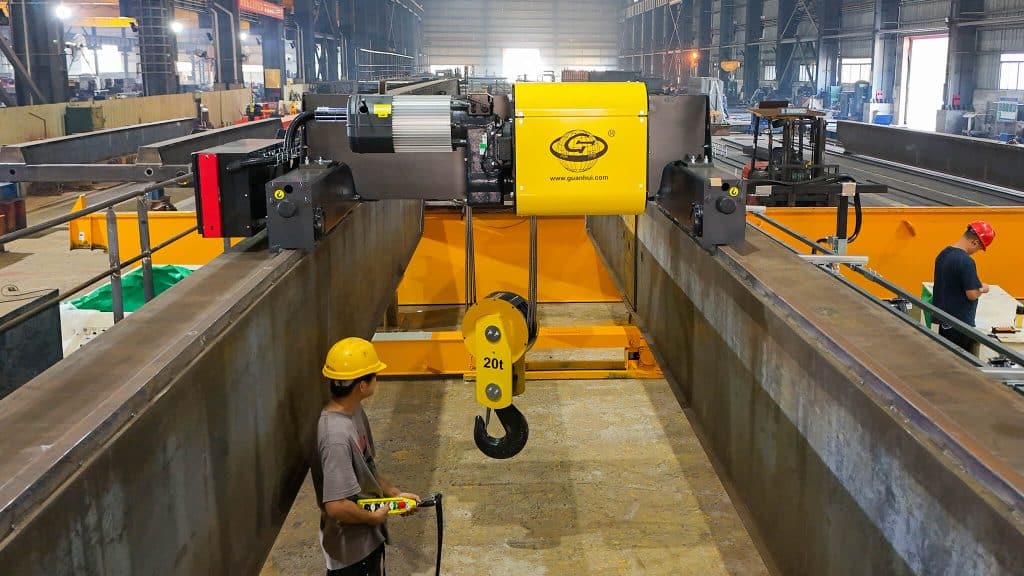

Our safety system

However, safety risks shouldn’t be the hurdle when chasing high productivity. For all these years in this industry, Guanhui has always kept safety as our priority, leaving nothing to chance in possible accidents at your site. We offer a mature safety system that significantly improves the margin of safety, safeguarding your employees and your business.

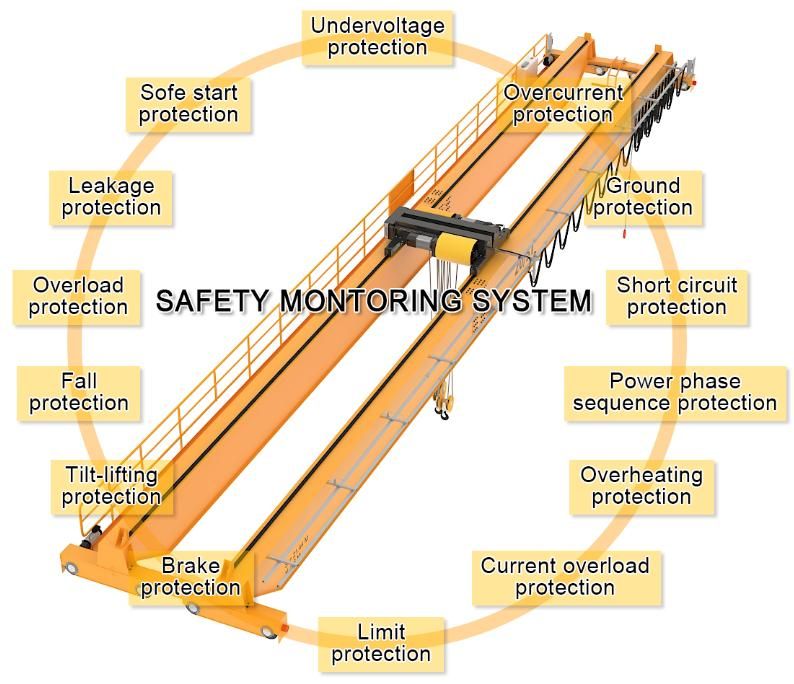

To keep safe and effective running all along, we have 20 standard safety protecting features and seven options.

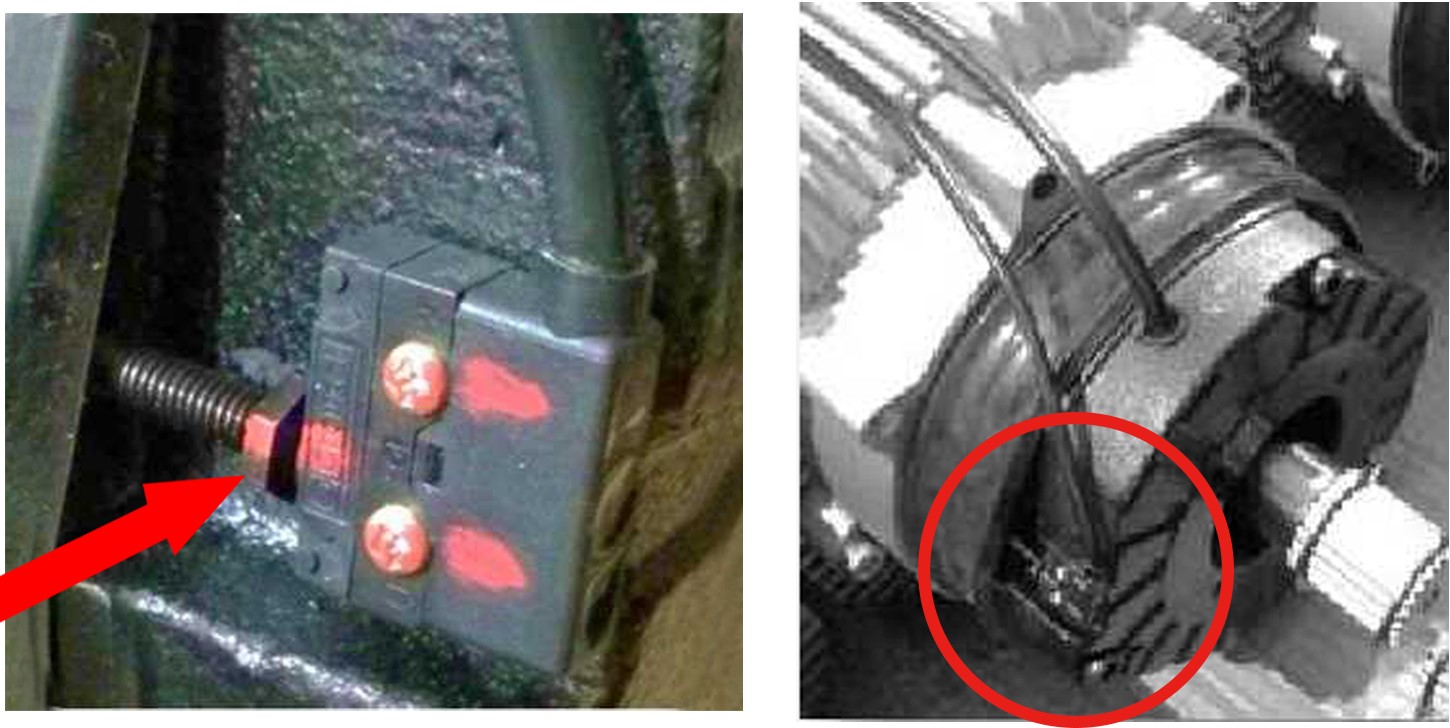

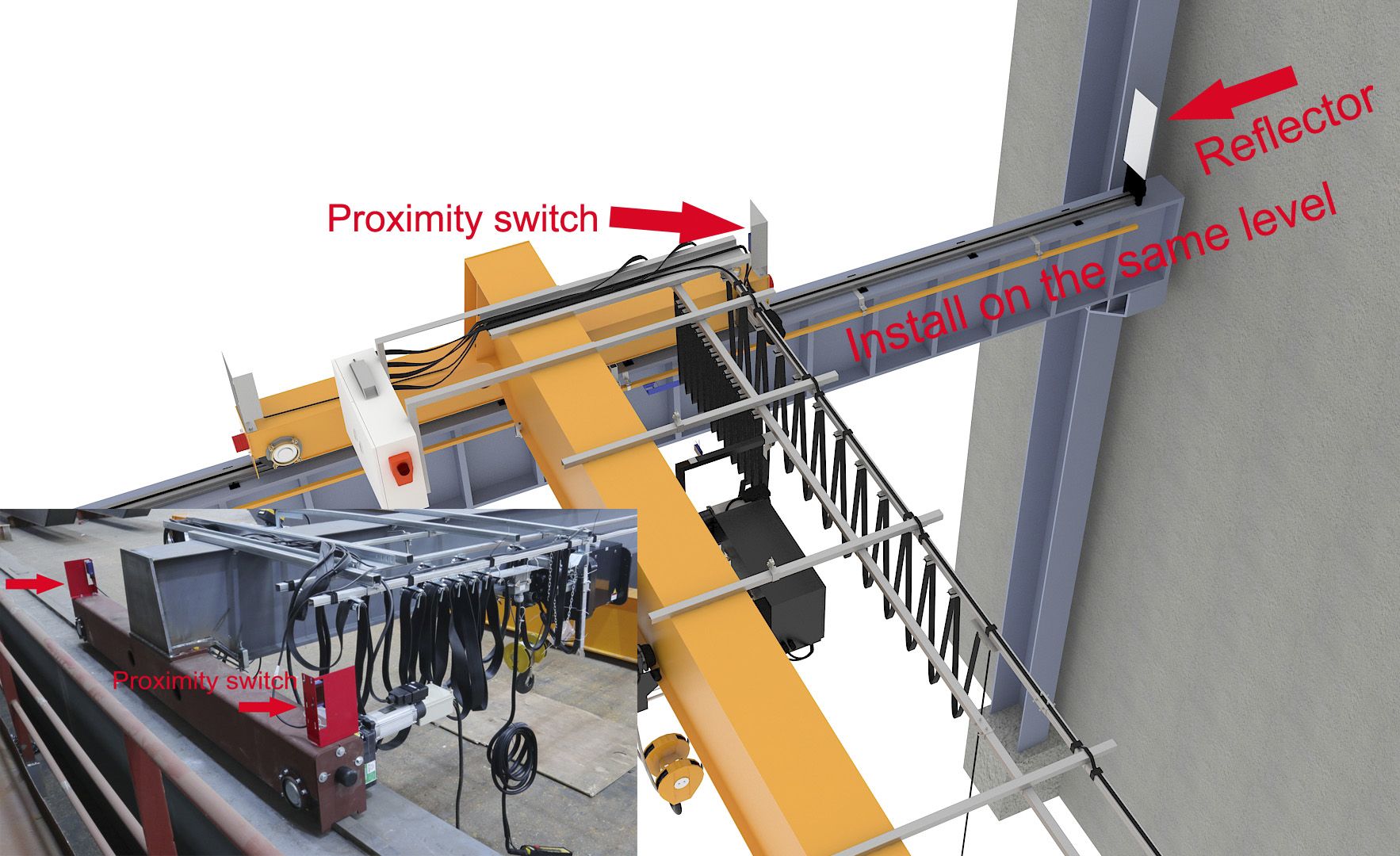

Anti-collision system

When there are multiple cranes operating in a constrained area, it is especially important to keep the cranes from colliding with each other or other equipment in the area.

The Anti-collision system is intended to help prevent collisions between cranes or their loads. When the crane or its load comes within a predetermined distance (0-6m set adjustable) of another moving or fixed object, the system either slows or stops the crane movement. This protects your cranes, people working around them, loads, building structures, and surrounding assets.

Overloading Protection

Though the properly trained operator should always be the first and foremost line of defense against overloading your cranes, under the pressure of achieving ever-increasing productivity, ever-expanding demands on crane equipment may lead to overload-related accidents. Our overloading protective device will prevent the crane from operating under overload conditions:

- Alarming up to 100% loading

- Alarming and downwards only up to 110% overloading

- Alarming and immediately stop up to 125% overloading

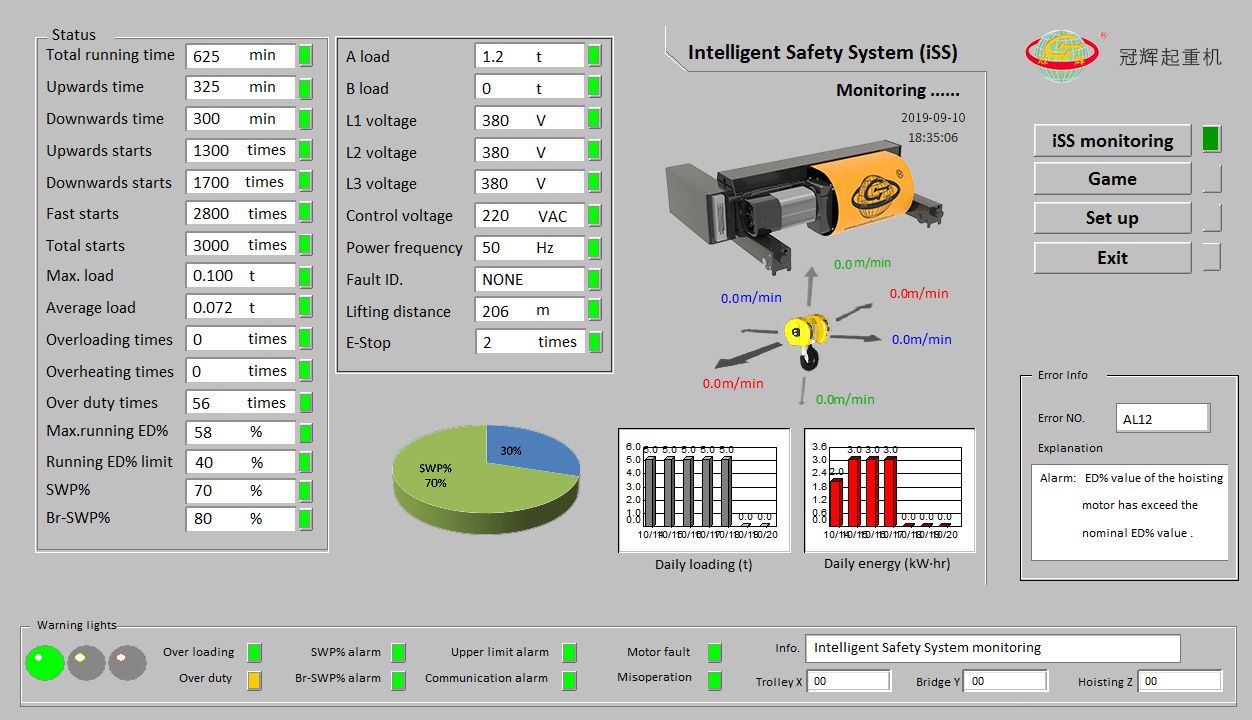

Safety Monitoring System

The crane safety monitoring system provides you with crane usage and operating information as well as records of brake service life, hoist overloads, emergency stops, and over-temperature occurrences, allowing for a timely response. The data can be used to help make maintenance decisions including parts replacement, maintenance intervals, and training for operators. The safety monitoring system also helps technicians quickly identify and correct the source of equipment problems so the equipment can be returned to service sooner – and reduce the expense of disruptions in production.

Manual Release

If an unexpected power failure occurs while the load is being lifted to a high altitude, the load can be slowly lowered to the ground using the hoist’s manual release button. This prevents the loss of machinery due to long-term load suspension, as well as potential safety accidents.

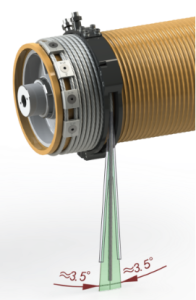

Tilt-lifting prevention has been designed to stop hoisting motion when tilt-lifting is detected. A tilt-lifting occurs when the hoist lifts something that has not been placed directly beneath it. Tilt-lifting can cause hazardous load swings and in the worst case – load drops.

Remote Controls

Aside from the pendant control, you’ll get a radio control that provides free movement for the operator and allows them to choose the safest place to operate the crane, and gives them better visibility of the load.

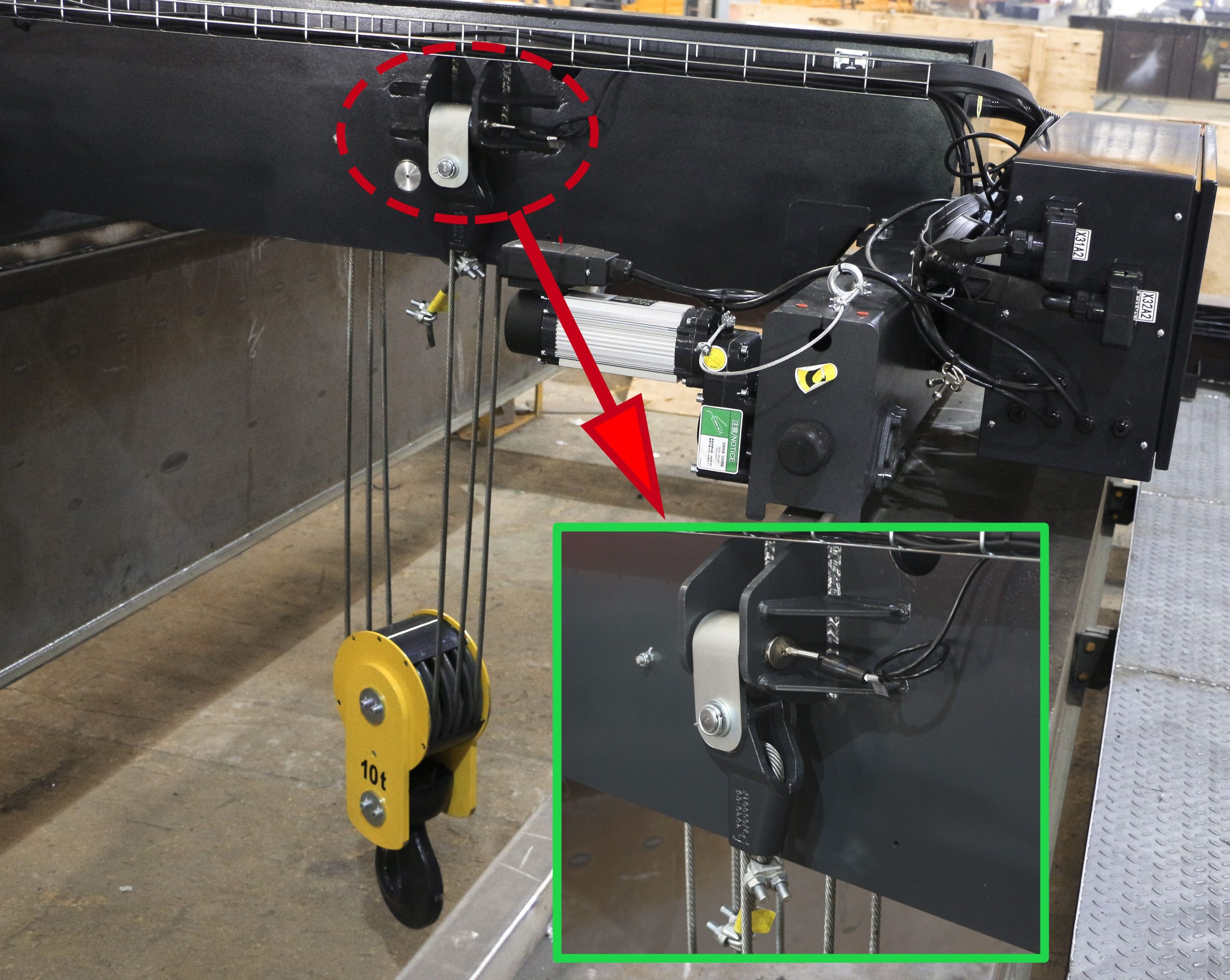

Over-braking protection

The Over-braking device will stop the lifting motor immediately in case the brake fails, to protect the load from slipping hook and falling. Recommended application of Over-braking protection: Heavy-duty loading in Coil lifting, Magnet & Grab, Paper coil, Stone Slab.