Each instance of crane failure is unique, but they are usually caused by similar circumstances. While most common crane failures are unavoidable and occur due to prolonged use, incidents where a crane fails unexpectedly can be detrimental for business.

Crane failure interferes with production, slows construction, which will extend time duration to add the cost, and even led to the stagnation of the project. Once delays in delivery times eventually lead to contract violations,which loss the profit and credibility and have a negative impact on the company's image

High cost of maintenance

Maintenance caused by crane failure includes the number of component parts, the time taken for inspection, the frequency of inspection, the number of parts to be repaired or replaced, and the extent of damage or wear and tear. That will cause a high cost of inspection,repairs and replacements.

Labor cost

If the crane failure will result in the upstream and downstream or even the whole production line operation stagnation, the result is not only caused by the equipment maintenance cost, the corresponding labor cost will also increase.

As lifting equipment, the crane can adapt to many working conditions. When encountering a harsh working environment, the failure frequency is relatively high. In addition, many parts of the crane may be aging, malfunctioning, or simply malfunctioning, resulting in expensive maintenance costs and downtime. If you want to improve productivity from a crane, you must know what causes crane failure.

Choose the wrong crane

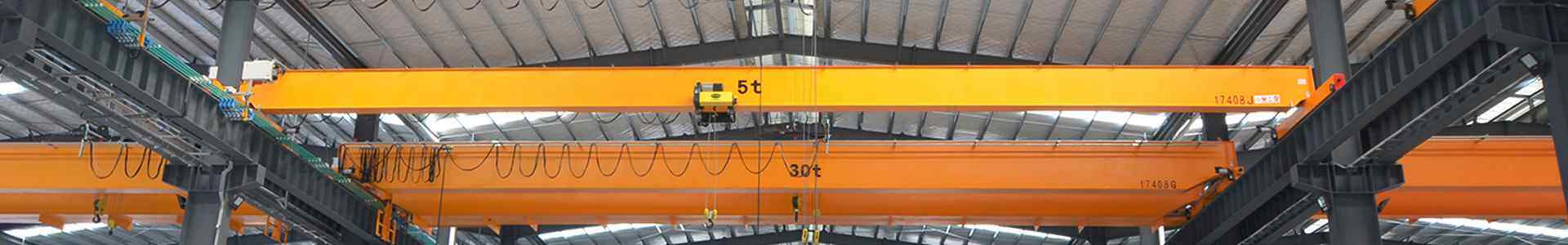

Choose the wrong crane is one of the main causes of crane failure. According to the crane's working level, working environment and use place, the crane has different specifications, capacity and function, so many factors need to be considered when choosing the crane, if you buy a crane that does not meet the working conditions,it is easy to cause crane failures during operation and lead to safety accidents.

Worn components

Like other machinery and equipment, the most common cause of crane failure is the wear of parts. Under long-term use or special working conditions, the parts of the crane may cause excessive wear caused by friction or corrosion, and eventually lead to crane failure, which will greatly affect the service life of the crane

Misoperation

Due to the crane operator's lack of attention, ability, awareness or familiarity with the use of the crane, the operation not in accordance with the safety operation rules cause to crane failure, and any mishandling of a crane and the swinging of its load will result in dangerous consequences.

How to reduce crane failures and improve productivity?

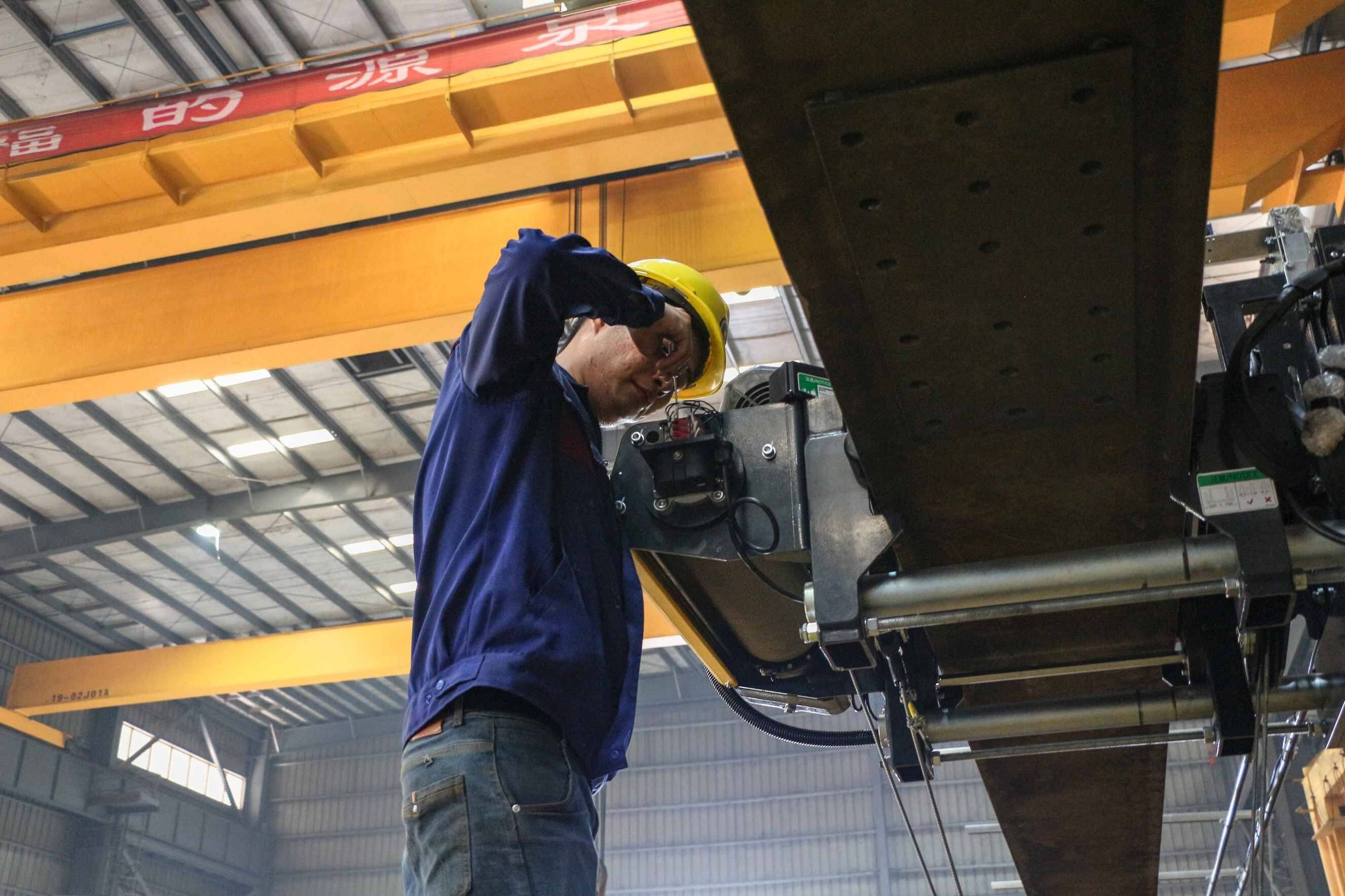

Do your cranes suffer from premature wheel wear, structural component failures,or drive faults? Have your crane operators complained that a crane is operating not clever or positioning incorrectly? If the answer is yes,you can continue to see how we can solve these problems from the source and reduce the risk of crane failure to the minimum is in line with the best profit of your business - not only to ensure the safety of crane operation, but also to save you a lot of costs due to failure and downtime and improve your productivity.

Maintenance free to less downtime

During the operation of the crane, the oil leakage of the gearbox and other parts or the lack of proper lubrication will accelerate the wear, leading to the failure of the crane that require downtime for maintenance.

However, our cranes have been filled with lubricating oil and fully sealed when they leave the factory, and are maintenance free throughout the life cycle, which greatly reduces the loss caused by downtime and maintenance and improves your productivity.Our maintenance - free parts are as follow:

- Lifting motor

- Lifting gearbox

- Lifting limit switch

- Crane monitor

- Hoist monitor

Reduce wear to extending the work life

Fatigue, aging, corrosion and wear of components will cause crane failure and affect crane life. In order to avoid this situation, the crane parts we use greatly reduce wear and tear, extend the work life of the parts, manufacture a long life crane.

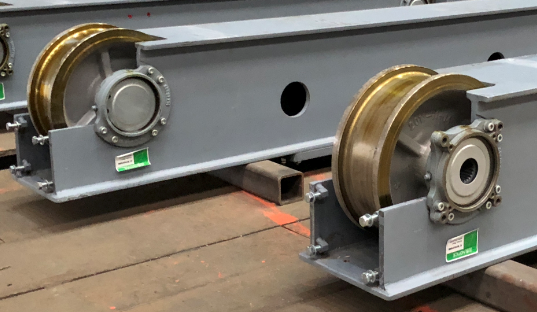

Throughout the course of a crane’s life, the wheels will naturally wear down due to normal use of the crane and will need to be replaced. To avoid premature wear on the wheels,our wheels made of the ductile iron with high strength, good hardness and good self-lubricating, which can greatly reduce wear and extend the work life.

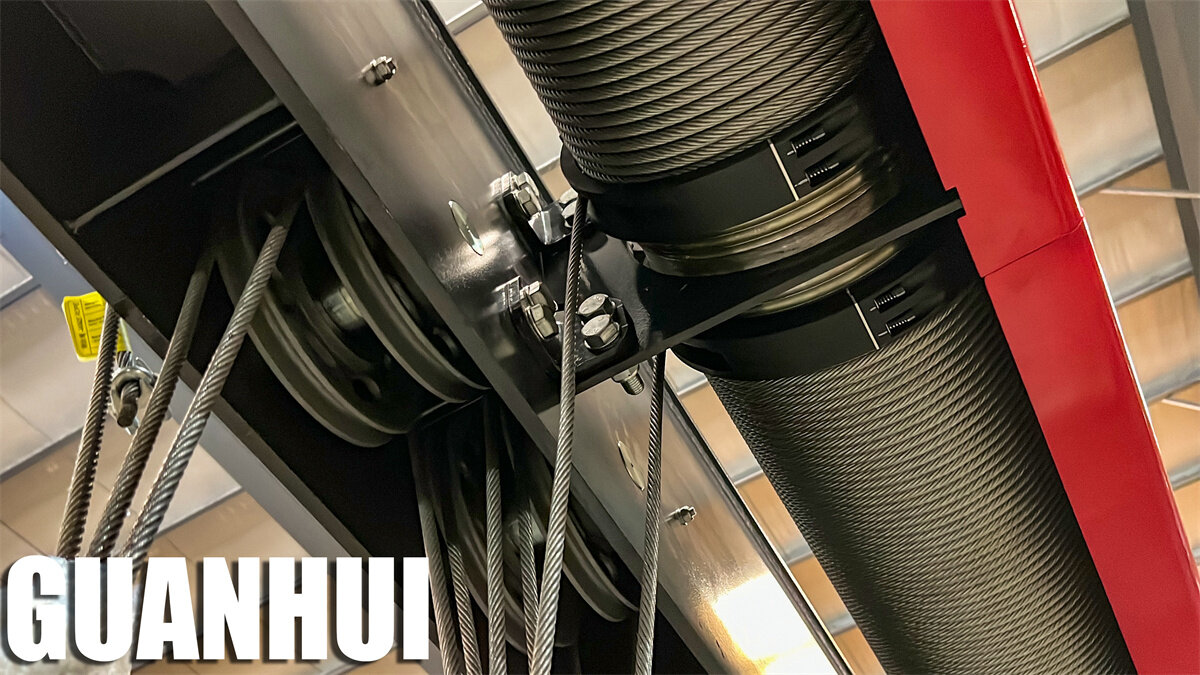

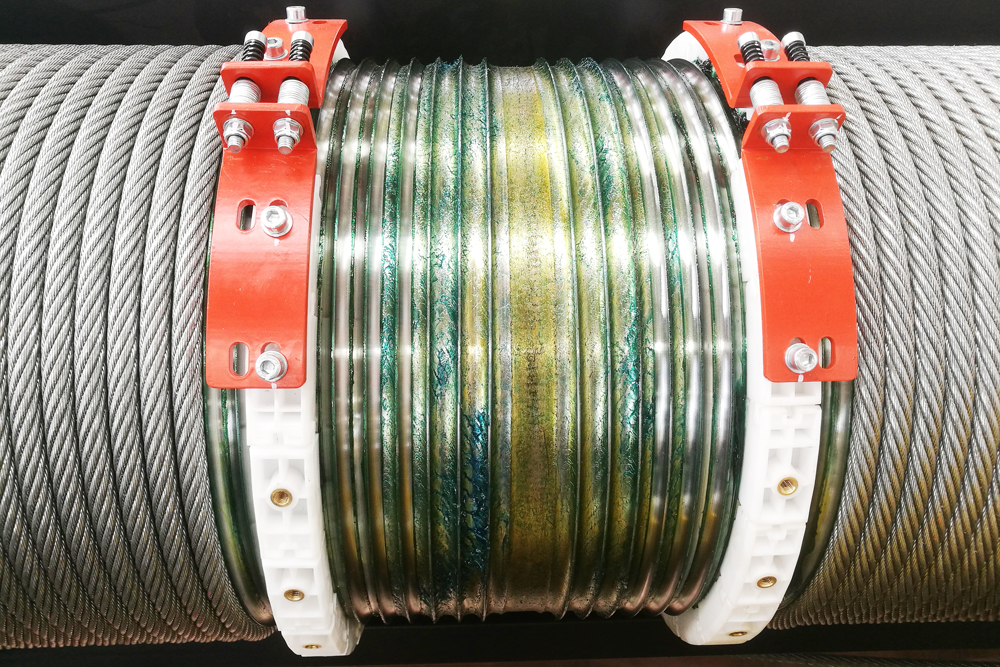

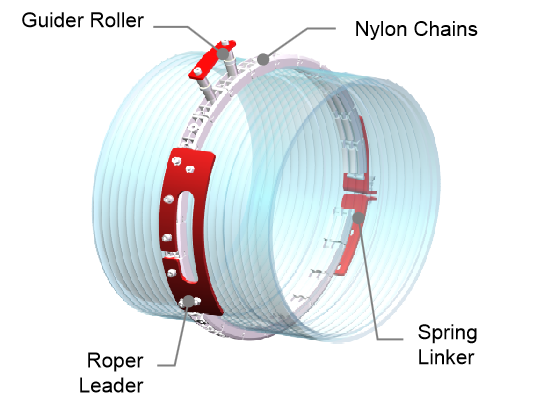

Our drums are designed with single-layer rope winding to avoid disorderly rope. The diameter ratio of the drum to the wire rope exceeds D / d > = 40, which is more than 50% larger than the traditional drum. The large-diameter drum can reduce the bending fatigue of the wire rope and extend the work life.

One of the most common reasons for the damage of wire rope is that the wire rope jumps out of the rope winding system, which leads to wire rope disorder, deformation, accelerated wear and so on and reduces safety. The all-round rope guider we use has good toughness and elasticity, which can guide the rope smoothly, adapt to oblique pulling and hanging, and has small wear on the wire rope and long life.

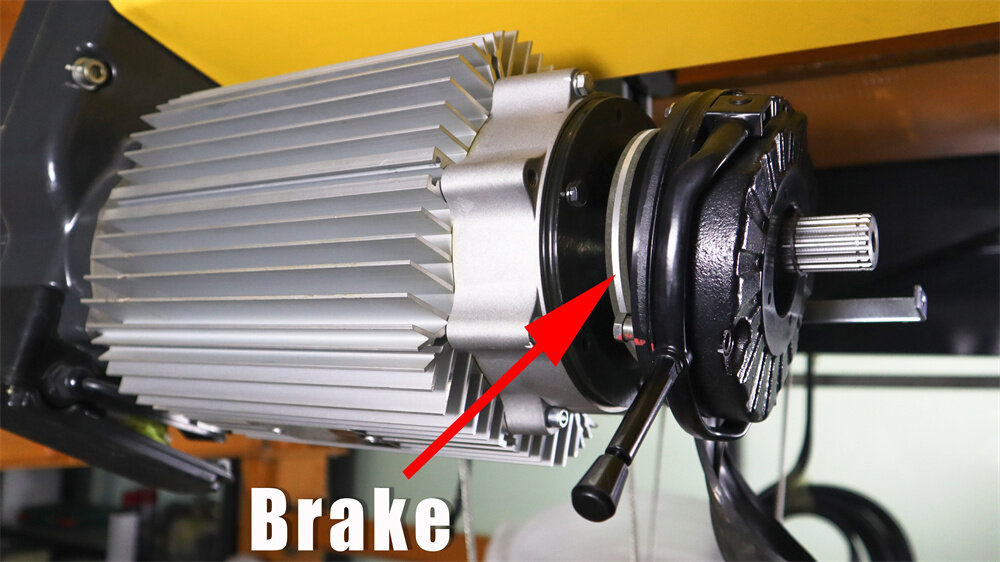

The heavy-duty brake pads we use are no adjusting for brake lining, have a long work life and conventional braking 1 million times.

When the crane is carrying heavy objects, obstacles or narrow passages need to be removed or re-planned to slowly move loads, which requires a lot of time. With our frequency conversion system, crane can flexibly and stably move loads to avoid obstacles through simple operation, and quickly and easily reach the designated area through the narrow aisle, effectively reducing the time required for moving obstacles, improving the stability of moving loads and the crane utilization. Our frequency conversion system has the characteristics are as follow:

- Anti-shake

- Anti-shock

- Precise positioning

- Frequency Control